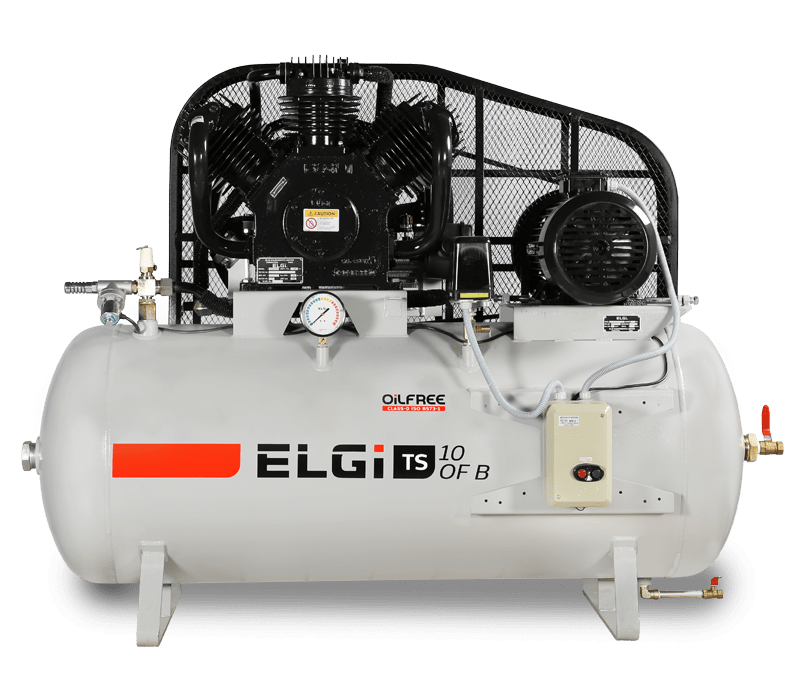

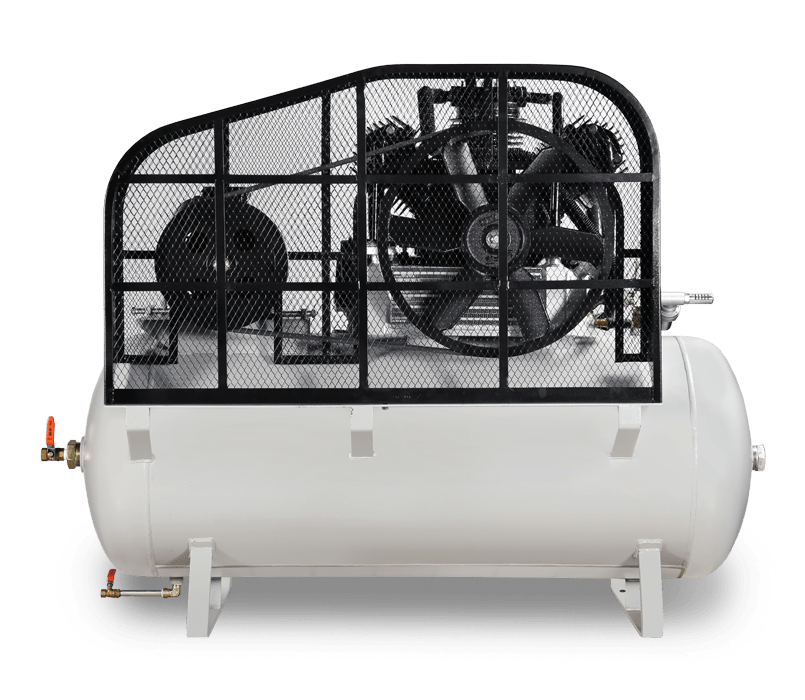

Built with a dry sump design and unique suction through crankcase design, this product meets the requirements of industries that need quality air without contamination like medical complexes, and food processing.

FEW APPLICATIONS

- Oxygen/Nitrogen generation plants

- Laboratories

- Research facilities

- Pharmaceutical industry

- Food processing

- Applications that are zero tolerant to oil in compressed air

- Electronics production

- Ozone generation

- Printing equipment

- Fermenters

- Packaging

FEATURES

- UNIQUE SUCTION THROUGH CRANK CASE DESIGN ENSURES NO UNWANTED VACUUM GENERATION IN THE CRANK CASE

- ROBUST CAST IRON BLOCK FOR LONG LIFE

- DEEP FINNED CYLINDERS FOR EFFICIENT HEAT DISSIPATION

- CYLINDER WALLS ARE SPECIALLY COATED FOR WEAR AND CORROSION RESISTANCE

- PTFE COATED PISTON & PISTON RINGS

- DELIVERY UNLOADER FOR AUTOMATIC UNLOADING OF COMPRESSED AIR IN THE DELIVERY PIPELINES

- FLANGED ALUMINIUM AFTERCOOLER FOR EFFICIENT COOLING